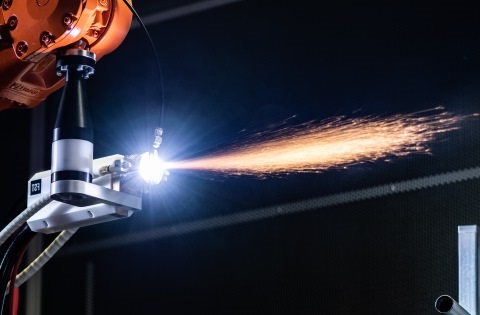

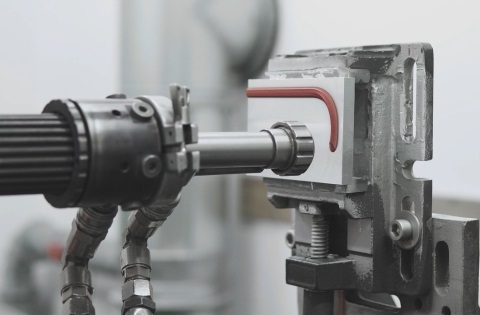

Thermal spray systems and equipment

FST’s modular thermal spray systems offer flexibility, precision, and high performance for modern coating needs. Our systems – including HVOF, plasma, cold-gas, arc wire, flame powder, and flame wire – can be adapted to your production setup, expanded as your business grows, and installed anywhere in the world.

How to select the right thermal spray process?

When selecting the right thermal spray equipment, it’s important to understand the differences between the available spray processes. Each method offers unique advantages depending on the application, coating material, and required surface properties.

- HVOF (High Velocity Oxygen Fuel): Produces extremely dense and hard coatings, ideal for wear and corrosion protection. Commonly used for carbide and metallic coatings in aerospace, oil & gas, and energy industries.

- Plasma Spray: Offers the highest process temperatures, enabling the deposition of ceramics, oxides, and high-melting-point materials. Excellent for thermal barrier coatings and electrical insulation.

- Cold Gas Spray: Uses supersonic particle velocity at relatively low temperatures, preserving feedstock properties. Ideal for oxidation-sensitive metals and dimensional restoration.

- Arc Wire Spray: Cost-effective and efficient for applying large metal coatings, often used for corrosion protection on structural components.

- Flame Powder Spray: Simple and versatile, suitable for applying metallic or ceramic coatings where extreme precision is not required.

- Flame Wire Spray: A low-cost method mainly used for corrosion protection and rebuilding worn surfaces.

By offering all these different technology options, FST ensures that your thermal spray equipment can be configured to meet exact process requirements, whether you need maximum hardness, thermal insulation, or long-term corrosion resistance.