HVOF Thermal spray systems

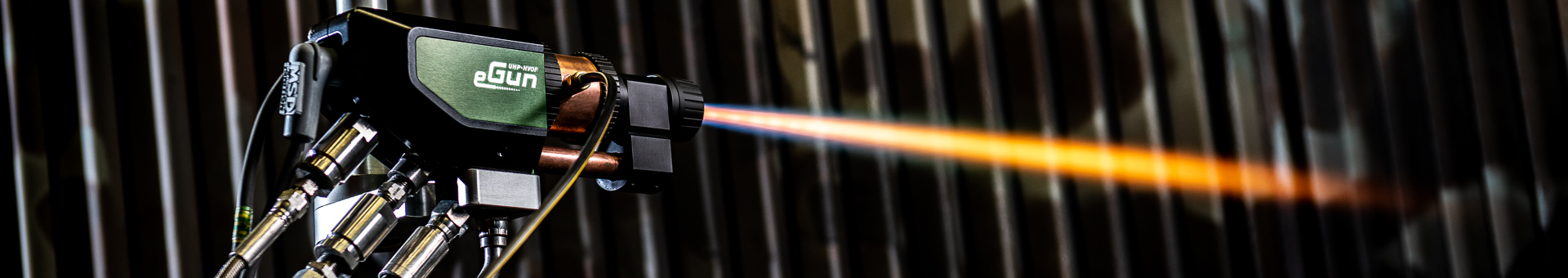

HVOF is a thermal spray process utilising the combustion of gases, such as hydrogen, methane, propane, propylene, acetylene, natural gas or liquid fuels such as ethanol or kerosene. Fuel and oxygen atomise and mix within the combustion area. This mixture is ignited at controlled temperatures and pressures resulting in a flame with supersonic velocity. Material is injected into the flame and propelled towards the substrate to form the coating.

HVOF Thermal spray coating process

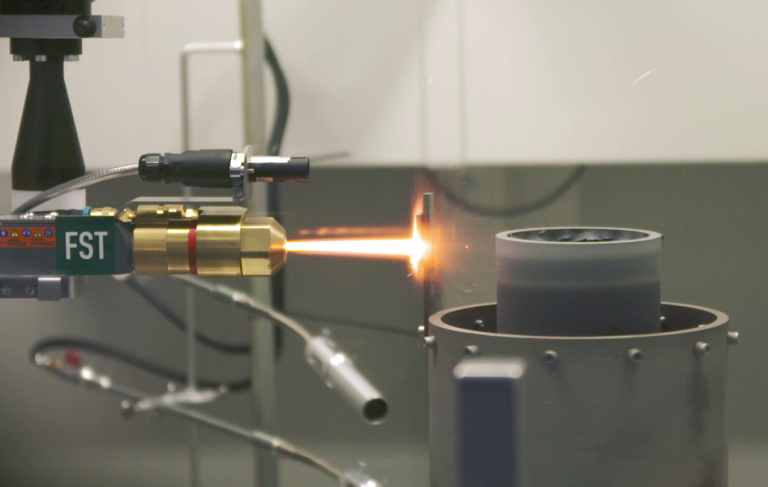

Fuel and oxygen are fed into a combustion chamber where they are ignited and combusted continuously. The resultant hot gas expands rapidly and exits through a converging-diverging nozzle. The jet velocity produced at the exit of the barrel (>2,000 m/s) exceeds the speed of sound. A powder feedstock is injected into the gas stream at various locations, dependent on the chosen Gun or Torch. The particles are then accelerated up to approximately 700 m/s.

The jet of hot gas and powder (spray stream) is directed towards the surface to be coated. The powder partially melts in the stream and deposits upon the substrate. The resulting coating has, among other attributes, very low porosity and high bond strength.

A wide variety of materials can be applied using the HVOF process in thicknesses ranging between 0.05mm to several mm.

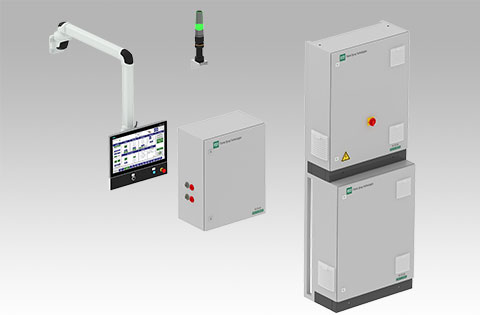

HorizonTM software

FST Horizon™ professional Thermal Spray Software – operates multiple thermal spray processes in one modular software platform. Increase your production output by using FST’s reliable, versatile, unmatched process control delivered by FST’s 50 Digital Series systems.

Frequently asked questions

FST offers a complete range of HVOF equipment, including liquid-fuel systems (HV-50 LF), mobile liquid-fuel units (HV-50 LF/M Mobile), and gas-fuel systems (HV-50 GF).

- Liquid-fuel HVOF equipment (HV-50 LF): Provides a broad operating window and is highly flexible, making it ideal for producing extremely dense, hard coatings such as carbides.

- Mobile liquid-fuel HVOF (HV-50 LF/M): A portable version designed for on-site repair and maintenance work where components cannot be moved to a spray facility.

- Gas-fuel HVOF equipment (HV-50 GF): Uses gaseous fuels (e.g., hydrogen, propane) for a cleaner process with simpler handling, making it well-suited for production of smaller components.

Choosing the right system depends on your application: if you need the highest coating density and flexibility, liquid-fuel systems are best; if you require on-site mobility, the mobile unit is the solution; and if you value ease of operation and clean fuel handling, gas-fuel systems are the preferred choice

More information about HVOF process?

High-Velocity Oxygen Fuel (HVOF) is a high velocity, low temperature thermal spray process used for the production of metallic and hard facing coatings. HVOF improves and restores a component’s surface properties through greater hardness, less porosity lower oxide content, higher bond strength, and a higher maximum thickness than a coating applied with most other thermal spray processes. HVOF coatings are therefore used in applications requiring the highest density and strength, whereby extending equipment life by significantly increasing erosion and wear resistance, and corrosion protection.