Introduction

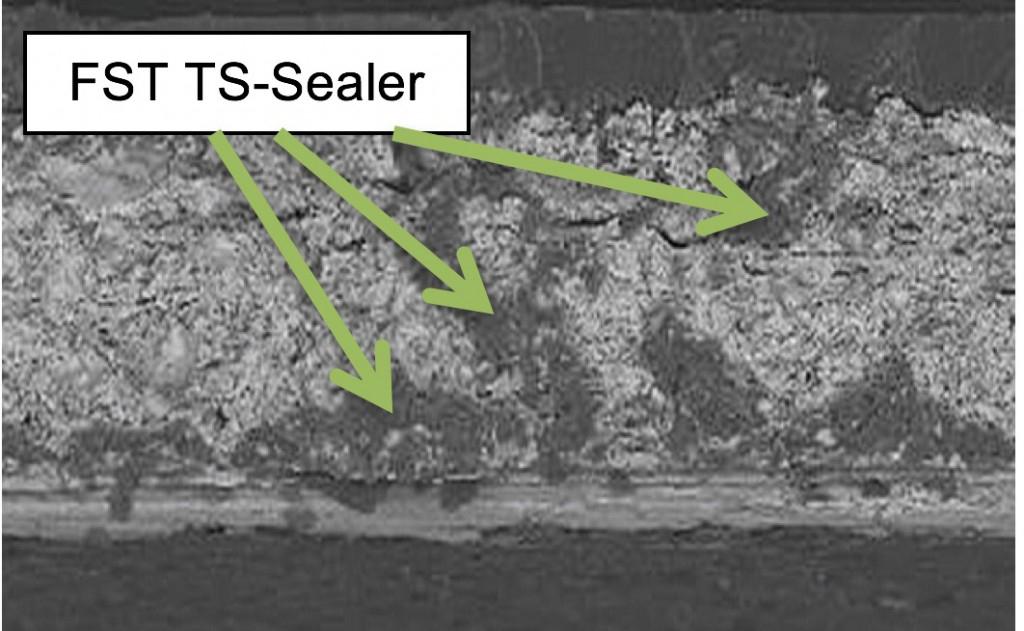

Thermal spray coatings always have process-related residual porosities. Due to the residual porosity coating might not be gas, vapour or liquid-tight. The consequence can be corrosion underneath the sprayed coating and finally might result in micro-cracks in the coating or even complete delamination of the coating.

Description

FST TS-Sealers are capillary sealers which penetrate the porous and micro-cracks of thermally sprayed coatings deeper than comparable products.

The versatile and straightforward application of FST TS-Sealer (brush or spray) makes it user-friendly – even on complex structures. Flame-, Plasma-, ARC- and even HVOF-sprayed coatings resist premature failure by sealing the porosity with FST TS-Sealer.

The FST TS-Sealer Products are materials designed to penetrate deep into the pores or cracks of thermal spray coatings. Once dried and cured, they form a protective barrier to gases and liquids that the coat is exposed to.

This barrier becomes even more critical in situations where a galvanic potential between the coating and the substrate is a concern.

Sealers are recommended for porous coating systems, such as ceramics, that are designed to be used in liquid or atmospheric chemical environments, and for metallic coatings that have higher nobility than the substrate. Coatings that are anodic with respect to the substrate may be sealed to improve coating service life.

In many applications, the porous nature of thermally sprayed coatings is an advantage, such as retaining lubricants to prevent wear. However, in some cases, it is best to seal the porosity, such for thin coatings or when a corrosive reagent or damaging environment is present, such as seawater, steam, dilute acids, corrosive gases or elevated temperatures.

Coating porosity can entrap corrosive elements, setting up an electrochemical attack on both the coating and the underlying substrate. This could lead to coating and bond failure.

FST TS-Sealers protect both the thermally sprayed coating and the metal substrate underneath.

In machine element applications, FST TS-Sealers applied before finishing, prevent contamination of the coating pores and provides a cleaner initial ground finish.

Sealers can also be used to fill coating pores where high pressures are encountered, such as hydraulic rams and pump shafts, preventing fluid seepage through pores.

Where ceramic materials are utilised for their dielectric properties, sealing of the coating helps to maintain dielectric constants. If left unprotected, coating porosity could lead to the absorption of moisture and contaminants, resulting in the form of unwanted conductive paths in the coating.

Typical Uses and Applications

- Pump seals, shafts, plungers and housings

- Bridges, trestles and other outdoor structures

- Hydraulic pistons

- Petrochemical plants

- Farm equipment

- Printing cylinders

- Pulp and paper machinery

- Marine equipment and structures

- Transformer cases

- Storage vessels, tanks and waste containers

There are many more applications where FST TS-Sealer can be used.

General Sealer Preparation and Application

As a general rule, all sealers should be applied after spraying and prior to finishing. Sealers have maximum performance when surfaces are clean, dry and free of oil, grease, dirt, corrosives, paint, mill scale and any other foreign matter.

All sealers should be cured prior to finishing. The heat generated during machining may cause premature and non-uniform curing of the sealer. Grinding uncured sealers may clog grinding wheels.

It is recommended that a light coat of sealer be reapplied after finishing to assure optimum sealing.

For maximum resistance to corrosion, all sealers must be fully cured before placing in service.

Handling Recommendations

- Sealers should be stored and handled with the same precautions as used for ordinary paints and thinners.

- Store in environmentally-controlled conditions. Avoid extremely hot or cold storage conditions.

- As some settling may occur, liquid sealers should be stirred or mixed thoroughly prior to use.

- Ensure that opened containers of liquid sealers are tightly sealed when not in use.

Safety Recommendations

FST TS-Sealer typically contains flammable materials and must be handled accordingly. See the MSDS (Material Safety Data Sheet) for the applicable product and localised for the country where the material is used. MSDS are available at FST.