Why the eGun™ spray gun has already been sold over 35 times

More and more companies moving towards FST’s sustainable HVOF technology and investing in the eGun™. With more than 35 systems sold since its introduction, this advanced HVOF spray gun has proven itself in the field, ensuring a greatly improved coating quality in many processes.

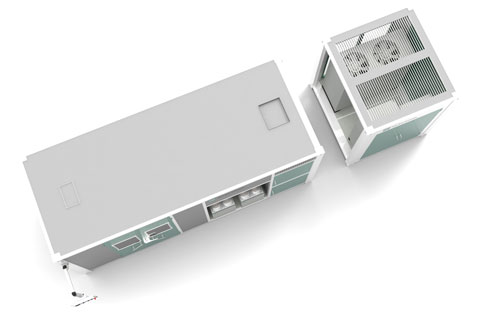

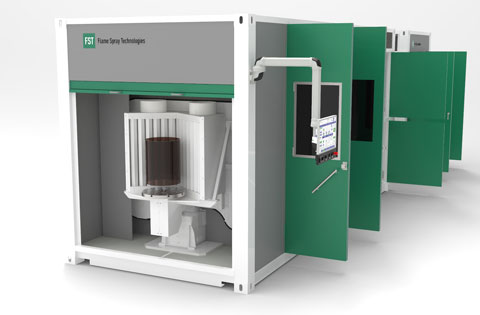

In response to customer requests and current market developments Flame Spray Technologies has developed The Coating Machine ™; a very complete flame spray production unit designed to service a wide variety of applications and markets. The Coating Machine™ is designed with standardization in mind, while offering customers multiple options to meet their specific needs.

A gun running at higher pressures, improving the coating quality

The eGun™ is a liquid fuel HVOF torch that uses ethanol as its fuel. The spray gun can operate at combustion chamber pressures up to 13 bar (188 PSI). This pressure is 3 to 5 bar (43 – 73 PSI) higher than conventional kerosene HP-HVOF systems. Higher pressures in the combustion chamber have shown to generate higher flame velocities which in turn generate higher particle velocities. A higher particle velocity results in improved coating density and better overall coating integrity. Moreover, with this gun it is also possible to run at low flame velocity for slow and hot parameters to produce very good bonding (rough) flash coats.

An overview of the eGun™ benefits:

- Larger window of operation vs kerosene, thus better control over the balance between kinetic and thermal energy of the particles.

- 30%-50% reduction in oxygen usage

- Up to 50% reduction in required cooling power

- No ash formation and less toxic fumes

- Environmentally friendly

- Consistent fuel

- Easy smooth system starts and ramp-ups

- Ability to run very fuel-rich, creating new coatings and application opportunities

More information or an upgrade of your existing HVOF system?

More detailed information can be found on our eGun™ HVOF spray gun and the HV-50-LF HVOF systems with liquid fuel page. Please contact our engineering department or one of the local offices for specific questions about your application and the correct choice of spray gun type.

New from FST: The Coating Machine™

In response to customer requests and current market developments Flame Spray Technologies has developed The Coating Machine ™; a very complete flame spray production unit designed to service a wide variety of applications and markets. The Coating Machine™ is designed with standardization in mind, while offering customers multiple options to meet their specific needs.

Plug and play - flame spray production unit

The new flame spray production unit is available in three different configurations to match your production needs. A Type I configuration has a turn table for loading multiple products, Type II is equipped with a station carousel and Type III has a 3500 mm spray lathe. Depending on the equipment chosen, the units can provide the following processes: HVOF, APS, Flame Wire, Flame Powder and Arc-Spray. Typically, the system will be operated using Flame Spray Technologies’ state of the art Digital 50 Series process controllers and the well proven Horizon Thermal Spray Software.

|

|

Features and benefits of The Coating Machine™:

- Shipped as a fully operational unit, production ready

- Cost reduction due to standardization, with options to choose from

- Pre-installed and commissioned equipment

- Essentially plug and play spray facility

- Robustly built to the highest standard

More information?

Read more about The Coating Machine™ on the product tab within the turn-key systems product information page or contact your local FST representative.

New FST Flame wire spray guns

For years FST promoted the FWS-20 flame wire spray gun. The FWS-20 gun will be dis-continued and will be replaced by an all-new range of hand-held or machine-mounted/robotic operated wire spray guns. The series will range from the manual operated, air motor driven FWS-10 to the semi-automatic FWS-21 and the automatically operated FWS-22 and FWS-30.

Spare Parts for the FWS-20 will remain available till December 31st 2022. After this date FST will no longer support the FSW-20.

What do the new spray guns offer

The new flame wire spray gun product range offers a solution for:

- a very wide range of applications

- light weight manual operation and heavy duty 24/7 applications

- applying both soft low temperature melting wires but also hard high temperature melting wires.

Model 1100 and 1200 gas control unit

The new model-1100 and 1200 gas control panels are designed to be used with FWS-10 and FWS-21/22 spray guns. The gas control unit are easy to use, low cost and provide the controls needed

More information or an update op you existing system?

More detailed information can be found on our flame wire spray systems page. Please contact our engineering department or one of the local offices for specific questions about your application and the correct choice of spray gun type.

New Accuraspray 4.0 sensor for optimal spray conditions

FST has succeeded to integrate a “Go/ No-Go” sensor into its system which operates both in manual and automatic mode. The sensor and its controls are called the Accuraspray 4.0, in reference to ensuring the spray process accuracy.

Operating principle

Before the torch is placed on a component to be coated, the spray plume is analyzed. An alarm is triggered when the spray plume properties move outside the predetermined acceptance range. This way of pre-monitoring ensures that the spraying conditions are optimal before a part is placed in the torch for coating. Operators are automatically notified if spraying conditions are not within predetermined process windows, reducing the risk of failure, ensuring coating quality and increasing production speed.

The plume is analyzed by measuring particle speed & temperatures and plum intensity, density & deviation. Now your operators can react and readjust before the process falls out of its green window and significantly improve your process CPKs and PPKs.

Suitable for HVOF, Plasma and Multi process systems

The Accuraspray 4.0 can be integrated in all new HVOF thermal spray, Plasma spray and Multi process systems of FST. If you would like more information about the integration into an existing system, please contact FST.

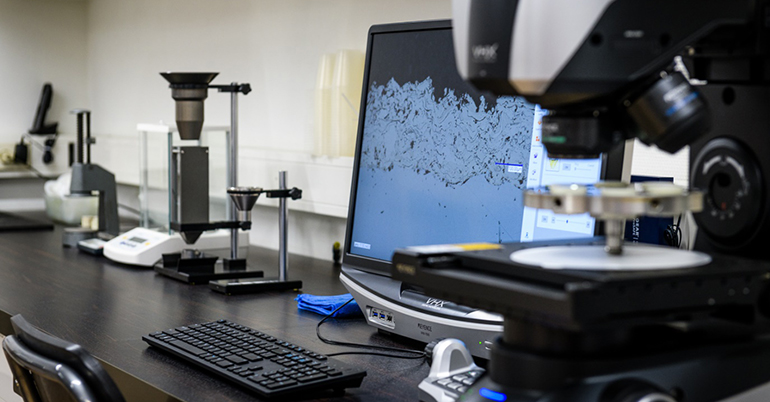

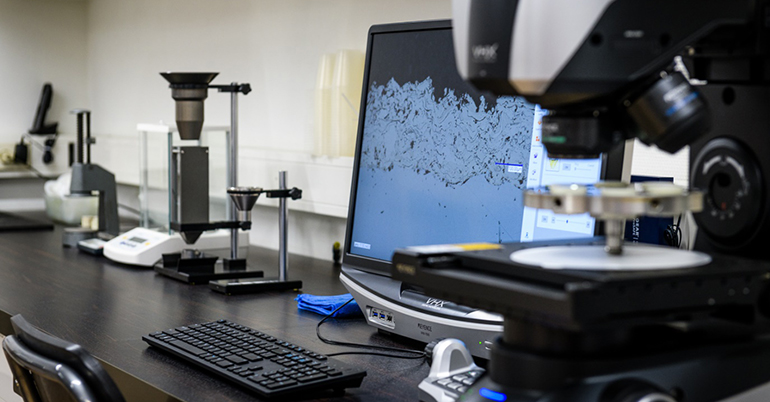

New Laboratory in Singapore and digital microscope for better R&D

In FST Singapore we have completed a state-of-the-art laboratory to support our Laser Cladding Activities (LCT) and our Thermal Spray Activities (FST).

The General Manager of FST/LCT Singapore, says “Our metallurgical laboratory will improve our capabilities to support our customers”. “Also, it will help us to better understand coating applied through Laser Cladding and Thermal Spraying”.

Next to installing a new metallurgical laboratory in Singapore, we recently upgraded our laboratory at FST in the Netherlands with a new digital microscope. The microscope not only provides the best possible micrograph images, but also has useful tools and features like; 3D look, photo stitching and powder size analysis. This technology will help FST to further develop products and support its customers with new services

Learn more about our metallurgical laboratory services.