Thermal spray

equipment

Flame Spray Technologies offer a wide range of thermal spray equipment to fit your specific application requirements. With more than 25 years of thermal spray experience and a product range that covers all major thermal spray processes, we can supply the right thermal spray equipment for virtually any situation.

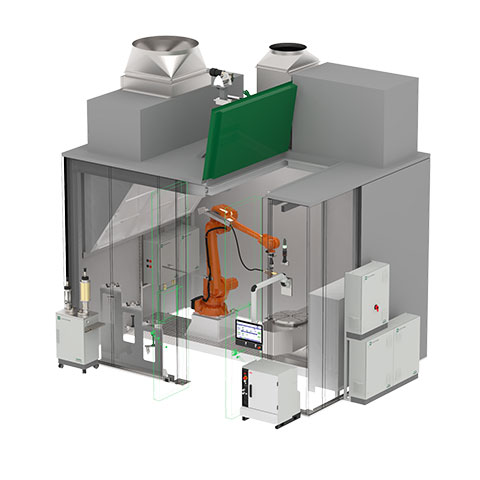

Turn-key systems

Turn-key coating systems are fully engineered integrated facilities, designed to offer tailor-made and best practice solutions.

Read more

HV-50-LF/M MOBILE - Liquid fuel

The HV-50-LF/M is a mobile stand-alone single process coating system using only state-of-the-art components and technologies.

Read more

Thermal spray systems

Based on your thermal spray coating requirements, FST offers a thermal spray system that is designed to your specific needs. FST systems are supplied as stand-alone or as a fully integrated part of your coating facility or production line.

Read more

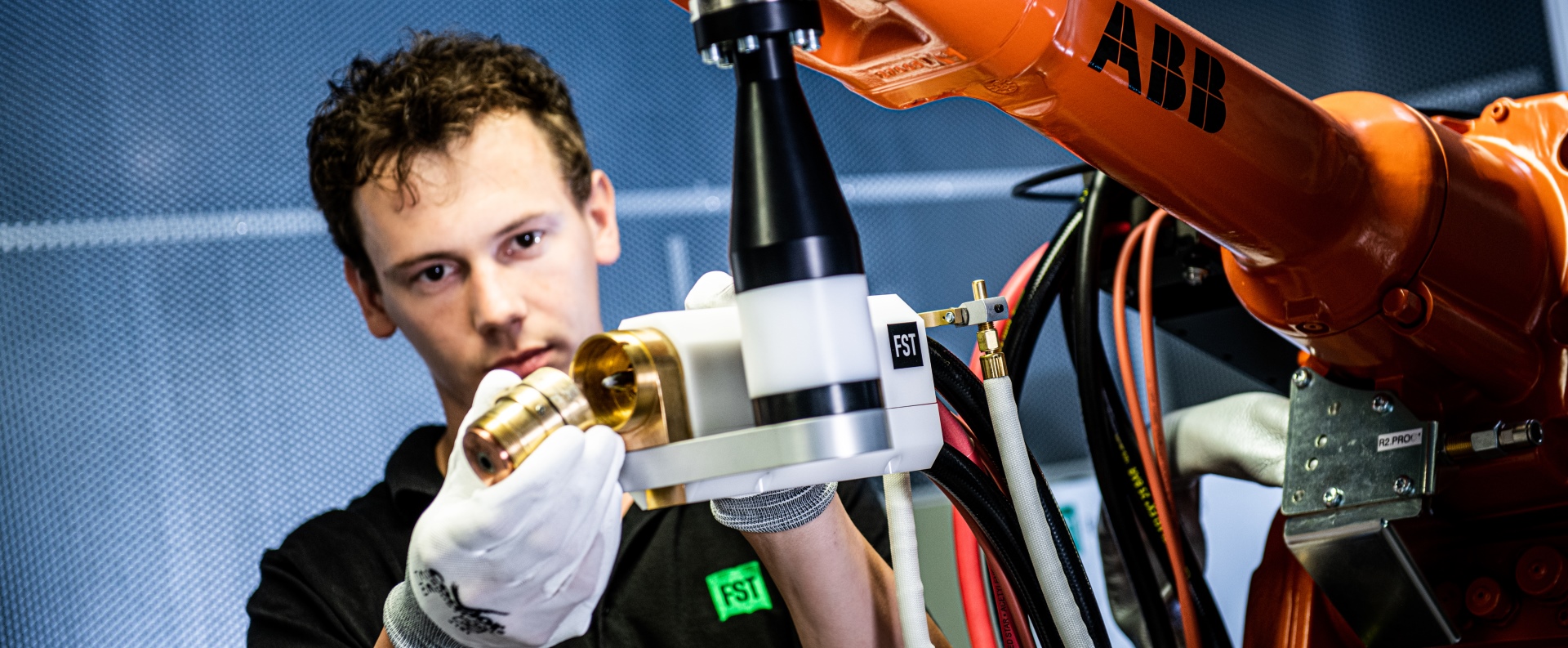

Auxiliary equipment

With a wide range of auxiliary equipment such as powder feeders, gun handling systems & robotics, chiller/cooling systems and dust extraction systems, FST offers all necessary products to support your coating activities.

Read moreThermal spray consumables

For every company operating thermal spray equipment, a reliable supply of high-quality consumable products is critical to ensure consistent coating production as well as guarantee the best possible and most economical performance.

Thermal spray powders

FST offers a complete range of powders including but not limited to metals and alloys, composites, ceramics and carbides.

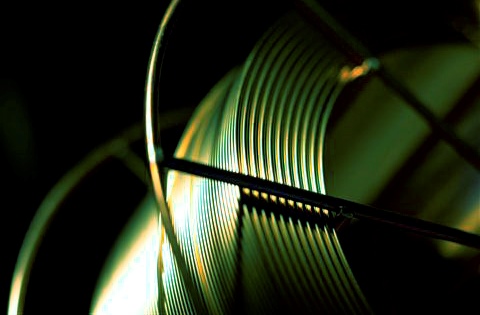

Thermal spray wires

FST offers high-quality thermal spray wires including but not limited to zinc, aluminium, stainless Steels, aluminium bronze, various cored wires, alloy 625.

Thermal spray spare parts

The continuation of your thermal spray activities is ensured by the availability of our spare parts and consumables. FST stock most common spare parts at the local FST offices.

Industry solutions

FST has the experience, knowledge and resources available to provide you with full support in finding solutions for your specific surface problems or requirements. FST has been successful in providing a wide range of industrial markets with thermal spray processes that have improved production efficiencies, extended the lifespan of its products and reduced their operating costs.

Industrial gas turbine

Overlay coatings and thermal barrier protection for industrial gas turbines extend operating life, and allow increased turbine entry temperatures (TET), leading to an improvement in thermal efficiency.

Paper & printing

Paper and printing companies looking to protect the surface of their manufacturing machinery and printing rollers benefit from thermal spray coatings to resist abrasion, corrosion and chemical attack, ensuring customers can produce high quality, consistent products whilst maintaining operational efficiency.

Aerospace

Thermal spraying is crucial in the manufacture of complex turbine and aerospace components. FST helps aviation manufacturers improve fuel efficiency, increase lifetime and performance expectations of components along with lowering maintenance costs.

Oil & gas

The use of thermal spray coatings in the drilling and extraction of oil & gas extends the life and improves the efficiency of downhole equipment and pipeline valves, thereby reducing maintenance and production costs. The use of thermal spray coatings will also reduce the impact on the environment compared to alternatives.

FST support and services

Maintenance & calibration

The Flame Spray Technologies service organisation maximises uptime by providing preventative maintenance and calibration services for your thermal spray equipment.

Metallographic laboratory services

Flame Spray Technologies offer thermal spray metallurgical laboratory services for coating, application and process development to understand coating properties and to assure coating quality in a production environment.

Surface Engineering & Innovation

Flame Spray Technologies, in partnership with Surface Engineering & Innovation Ltd, can provide materials, coating and application development services.

Quality & project engineer

"Quality is also a mindset and a critical element of everything we do at FST"

Coördinator Technical Operations & Aftersales

"Performing maintenance and calibration services is only part of the job, listening to the customers and following-up on it is also of great importance"

Sales support

"Key to being a good sales support employee is having empathy for the customers business and situation"

More information

Flame Spray Technologies (FST) is a leading global supplier of thermal spray solutions and services, including turnkey systems, stand-alone equipment, spare parts, spray materials (powders & wires), equipment service and calibration, laboratory services and application consultation. We are a specialist company providing solutions tailored to resolve your specific problems and challenges. As a dynamic and innovative hands-on company, we are flexible, responsive, design practical products, comply with current standards and offer new and increased benefits to the industry. The eGun™ ethanol-fueled HVOF Technology is a good example of such a product.